Value Added Services

Grade Verification, Eddy Testing, & Bar Straightening Near Chicago

In addition to primary services such as centerless and titanium grinding, Ace Grinding is proud to offer a variety of secondary services that can help you verify the grade of your materials, inspect them, and even straighten bent or damaged bars. As is with our precision grinding services, Ace Grinding aims to exceed our customers’ expectations by providing reliable, high-quality services performed on time and on budget. Contact us today to learn more about how our special value added services can benefit you.

Material Grade Verification

Ace Grinding is capable of determining and/or confirming the grade of your material, not only quickly, but without damage to your sample. The advantages of our grade verification process include:

- A tube-based system that eliminates costly resourcing and loss of speed

- Multi-element analysis in a single measurement

- Definitive positive and negative classifications

- No isotope licensing or travel restrictions

- An ergonomic, lightweight design

- A versatile PDA platform

- Easily measuring uneven surfaces

- Field-portable X-ray fluorescence (FP-XRF)

Many of these advantages hinge on the fact that we utilize XRF spectroscopy for qualitative and quantitative elemental analysis of your sample, which comes with the distinct benefit of being non-destructive, fast, and relatively affordable. These benefits stand out even more when compared to other competitive grade verification methods, such as Atomic Absorption Spectroscopy (AAS), Inductively Coupled Plasma Spectroscopy (ICPS), and Neutron Activation Analysis (NAA).

Additionally, XRF spectroscopy offers a fairly uniform detection limit across a large portion of the periodic table and is applicable to a wide range of concentrations, from 100% to few parts per million (ppm). Analyses are generally restricted to elements heavier than fluorine.

Eddy Testing

Eddy current inspection (or Eddy testing) is just one of several NDT methods that can be used to conduct examinations. However, the difference between Eddy testing and other NDT tools is just how many examinations it can be used to perform. When used correctly, Eddy currents can be used for:

- Crack detection

- Material thickness measurements

- Coating thickness measurements

- Conductivity measurements for material identification

- Heat damage detection

- Case depth determination

- Heat treatment monitoring

Ace Grinding’s MAC Encircling Coil Tester is capable of testing up to 0.7500″ with a maximum length of 12 ft. In addition to sensing surface and near-surface defects as well as small cracks, this equipment is very portable and offers immediate inspection results. While some minimum part preparation is required, Eddy testing is also more capable of inspecting complex shapes and sizes of conductive material.

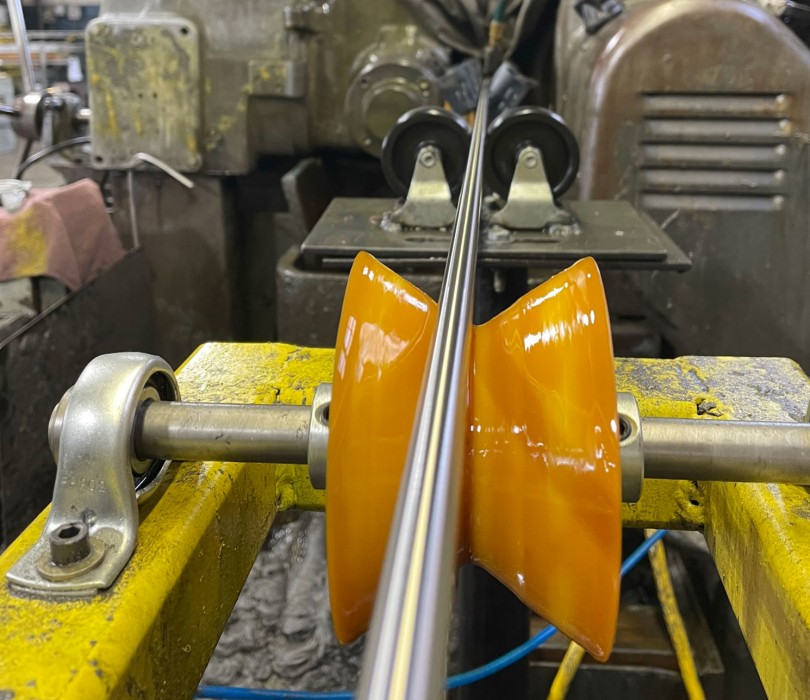

Bar Straightening

As a machine shop manufacturing to tight tolerances, it is your job to ensure you are working with straight bar stock regardless of your customer, but especially in critical industries, such as defense and transportation. Occasionally, bar stock can be damaged during the shipping process or even warped during heat treatment. Ace Grinding’s bar straightening services save you from these challenges while preventing scrap material and improving efficiency. We are capable of straightening bar stock between .125” OD to 1.0000″ OD to .008″ per foot TIR with a maximum length of 18 ft.

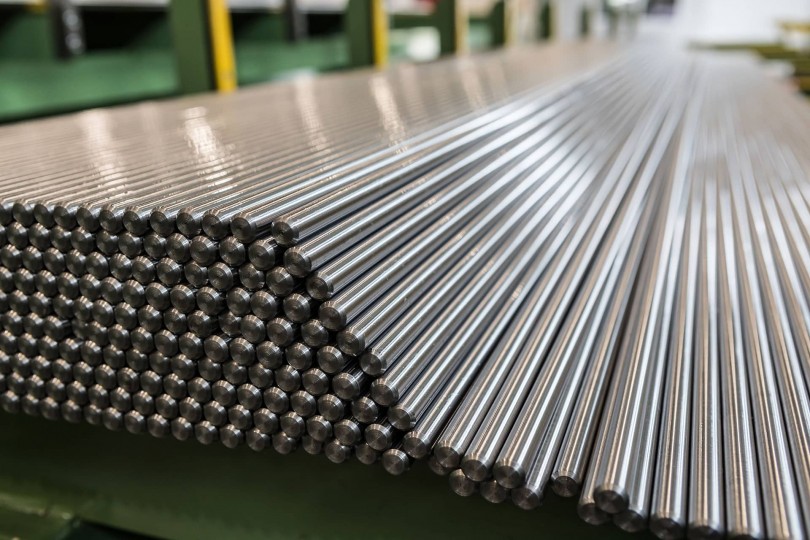

Made To Order Cut & Chamfered Bars

Ace Grinding uses high-quality equipment such as heavy-duty bandsaws and a custom chamfering machine to produce made-to-order cut and chamfered bars for our customers. We understand that our customers may run a variety of machining equipment and are prepared to meet a wide range of bar chamfering requirements for those seeking stainless steel, carbon steel, or alloy steel bars. Chamfered bar stock helps feeders run efficiently, saving you time and money during the CNC machining process.

Quality Satisfaction & Reliable Grinding Services

As an ISO 9001:2015 provider of high-quality precision ground bar stock, Ace Grinding adheres to a Quality Management System designed to consistently meet not only industry standards but customer standards as well. We realize that your business depends on us providing superior quality grinding services, and that is why we are committed to producing reliable products while staying on time and on budget. In addition to offering fast quotes and lead times, Ace Grinding can even facilitate delivery with carriers on your behalf. As your reliable precision ground bar stock supplier, we will always strive to exceed your expectations wherever possible.