Centerless Grinding Services

Centerless Grinding Services Near Chicago

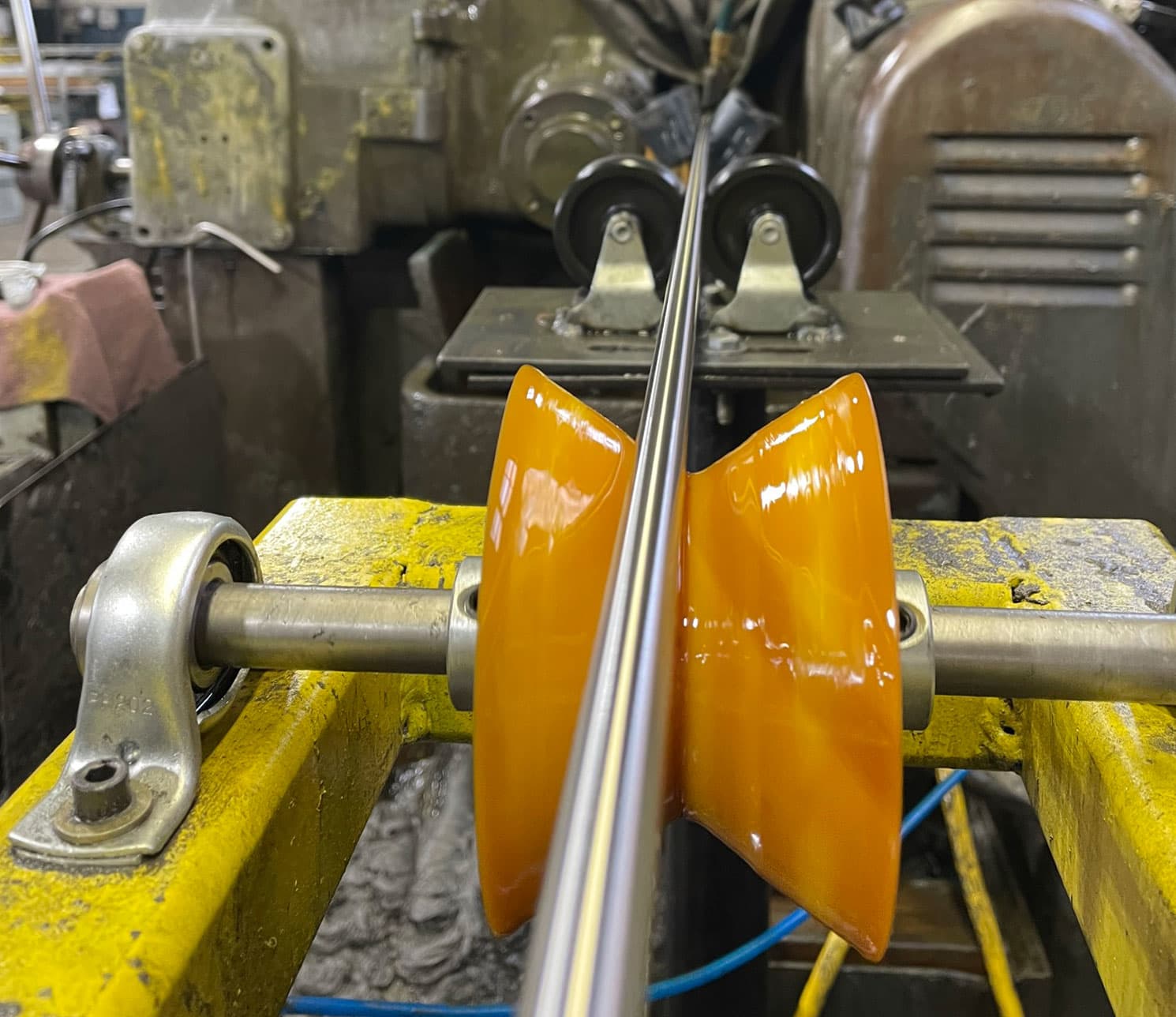

For precision ground and polished bar stock, Ace Grinding utilizes centerless grinding, which allows for the tightest tolerances required by industry as well as individual customer specifications. In addition to refining cold finishing processes, centerless grinding enhances factors such as roundness, straightness, and even surface finish. Precision ground bar stock is commonly used when a specific material composition is required, and when you come to Ace Grinding, you can count on reliable tolerances, dimensions, and finishes along with a fast turnaround.

Ace Grinding’s ground products are used for TG&P, BSQ, and beyond. Whether you are looking for a tight fit for a bearing, enhanced straightness, or a smooth surface finish for coatings to adhere to, our precision ground bar stock can help. We know what it takes to consistently provide superior precision ground bar stock to machine shops around the world. To learn more about our centerless grinding and precision bar stock services, contact our knowledgeable staff today.

Centerless Ground & Polish (CGP)

Through the process of Centerless Ground & Polish (CG&P), Ace Grinding ensures precision ground bar stock will perform with consistency. Centerless ground bar stock benefits machine shops that utilize CNC turning and Swiss machining operations as it reduces set-up time and scrap material.

Turned Ground & Polished (TG&P)

When you have high-performance requirements demanding precise roundness, straightness, and surface finish, Ace Grinding’s Turned, Ground, and Polished bar stock is your solution. In order to avoid early wear and tear on shafts and bearings, metal shafts being crafted for high-speed applications require a high degree of precision. To achieve this level of precision, Ace Grinding uses a process known as Turned, Ground, & Polished (TGP). As the name implies, this is a three-step process that can turn coarse, imperfect metal rods into straight shafts with smooth finishes. Purchasing TGP bar stock saves customers not only the time it would take to have raw materials turned, ground, and polished, but the money that would need to be spent on equipment, labor, and materials.

TGP shafting begins with hot rolled or cold drawn bar being turned in a lathe for excess material to be shaved off. Once the steel bar has reached its intended size, it is ground with a grinding wheel to remove an even smaller amount of material that could cause uneven wear or balancing issues. As soon as the proper dimensions are met, the bar is finally polished with a polishing wheel, giving the bar its smooth surface. Once all is said and done, we are left with a turned, ground, and polished bar that can be used for tool shanks, pistons rods, bolts, axles, motor shafts, tie rods, and more.

Bearing Shaft Quality (BSQ) Stainless Steel Bar

When it comes to bearing shaft quality requirements, you will find Ace Grinding gives customers the critical repeatability that they rely upon. A properly sized bearing shaft with a smooth, polished surface can extend not only the lifespan of the shaft itself but the full bearing assembly. That is why we insist on using nothing but the best Bearing Shaft Quality (BSQ) bar to create bearing shafts for precision tolerance bearings. Bearing shafts require reliability and repeatability, something that Ace Grinding has been offering customers for over 60 years.

Contact us today to learn more about our centerless ground bar stock.

Ace Grinding Value Added Services

Request a Quote

"*" indicates required fields